A team from the Rolls-Royce Applied Technology Group in Singapore has announced a new global patent – with a dozen more in the pipeline – relating to the electrical power systems responsible for powering some of the most complex aerospace, defence and marine engines.

Singapore Director Bicky Bhangu led a team of recent graduates (Chandana Gajanayake, Sivakumar Nadarajan and Mohamed Sathik) in their five-year journey as they gradually took on more responsibility, while also learning how to collaborate and share ideas.

Their work has resulted in new technology that will allow us to monitor the health of an engine’s electrical power system, optimise the power flow so that it’s fuel-efficient, reliable and available across its lifecycle.

Adding intelligence

Five years ago, Bicky first identified an opportunity for Rolls-Royce to develop a more intelligent electrical power system and communications network between the power electronics, electrical machine and the control system. The increased intelligence helps to predict and prevent faults, which in the electrical world can happen quickly and with very little warning.

As a business, we’ve become increasingly service and customer oriented. At the same time, the amount of data that has become available and the complexity of engines have skyrocketed.

For Bicky, the key was transforming data from the electrical power system into information to deliver benefits for the customer:

“An electrical system switches on and off very quickly, and can produce over 60,000 pieces of data a second (data that can take on a finite value). That means there are 60,000 data points that need to be analysed so we can observe the health of the electrical system and then make informed decisions.”

And aircraft are becoming increasingly reliant on electrical power, which presents new challenges.

He elaborates:

“A 787 Dreamliner has a fantastically innovative and complex architecture because of the many systems that rely on electrical power, from controlling air and humidity in the cabin to powering the movies you watch and heating up your dinner. If you consider how much electrical power would be needed for each passenger to boil two large electric kettles throughout the journey; that would give you an idea of how much electrical power is required.”

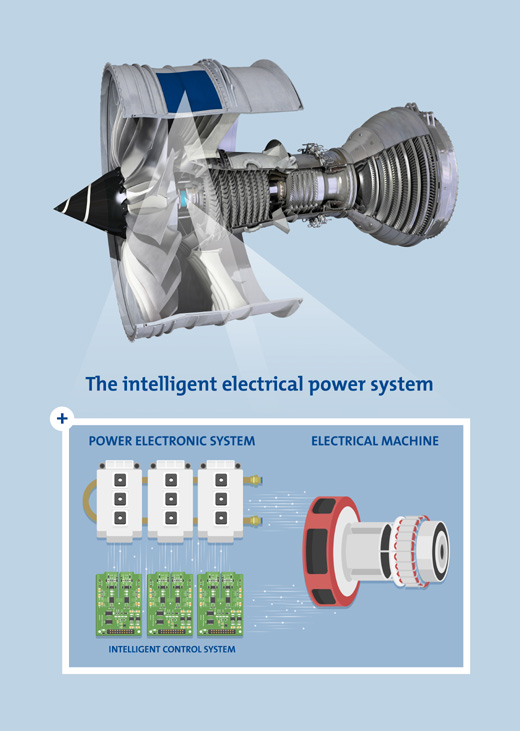

An electrical system is made up of three main things: the power electronic system (which manages the voltage and current to control the flow of electrical power), the electrical machine (a generator attached to the gas turbine engine) and the control system. The control is the brains of the operation, and it makes the whole electrical system work efficiently, safely and reliably.

Developing intelligence for equipment health monitoring for electrical system architecture

There are already many world-class power electronic companies and a plentiful supply of electrical machines. But there was a gap in the market for a power electronic system that was personalised for the needs of the aerospace industry, with built-in and configurable intelligence.

If successful, this would allow information to be deduced from the huge volumes of data collected from the environment and the entire electrical system.

The idea was that by making the system’s brain even smarter by introducing health monitoring intelligence (which Bicky likens to strapping a Fitbit onto the entire electrical system), we would be able to increase reliability of the system and help our customers optimise the energy management of the complete electrical power system (and therefore reduce fuel consumption).

Creating an innovation-friendly culture

The first step involved assembling a team of three electrical engineers from across Southeast Asia, who was supported by Rolls-Royce teams in the UK as well as academics and specialists in Singapore.

To cultivate a breeding ground for innovation, Bicky established a few cultural norms: sharing ideas – even seemingly silly ones – was in, but counter-productive practices like being glued to a presentation on a laptop (rather than actually talking) and staying late just because “the boss” hasn't left yet, were out.

To set an example, he would make a habit of deliberately voicing out-of-the-box ideas and would regularly be the first to close his laptop, pick up a marker pen and start drawing on a whiteboard. He encouraged his team to collaborate, ask questions, share ideas and take ownership of their individual sections.

They may not seem like radical changes, but they were important steps that helped to gradually create a certain type of culture that encouraged creative thinking.

Bicky elaborates:

“The problem was too big for us to work in silos, and our team was too small for a hierarchy. Plus, I knew that the team would eventually develop so much specialist knowledge in their individual areas of research that they would soon know more about their area than anyone else, so I had to build their confidence and make sure they were ready to take on that responsibility.”

Each team member clearly understood the purpose of the research, the milestones that lay ahead and the impact that success could have on the business, which helped keep them motivated throughout the five-year project.

Putting an idea to the test

One of the most exciting moments was when they were tasked with designing their dream lab at Nanyang Technological University (NTU), complete with all the tools they needed to test their ideas in a sandbox environment. This meant they were ready to take the step from dealing with simulations and theory towards developing real world hardware solutions. The moment they stepped into the new lab, the journey from simulation to validation began.

And having developed simulations of the concept and built the hardware to test it, the team is delighted to announce that they’ve been awarded a global patent in the area of Equipment Health Monitoring for Electrical Systems, with a dozen more in the pipeline.

Speaking about the progress so far, Bicky says:

“I’m proud of what we’ve achieved as a team. With electrical engineering, you’re dealing with things like voltage and currents that you can’t actually see, so it can be hard to visualise the results of your work. But, we’re now closer to seeing our research enter the real world, and my personal hope is that this shows any young person with an interest in science and engineering that they can make a real difference in the world.”

Meet the team behind the patents

- Bicky Bhangu, Singapore Director led the core team. Bicky began as Team Leader of Electrical Systems and in 2011 he became Chief of Electrical Systems.

- Chandana Gajanayake specialised in the power system architecture and control.

- Sivakumar Nadarajan specialised in the electrical machine and intelligent algorithms. He’s currently embarking on PhD research at the National University of Singapore with Rolls-Royce.

- Mohamed Sathik was the specialist for the power electronics and intelligent algorithms. He’s currently embarking on PhD research at Nanyang Technological University in Singapore.

Developing intelligence for equipment health monitoring for electrical system architecture

Electrical System

Includes:

- The power electronic system

- The control system

- The electrical machine

Generates the electrical power required on-board the aircraft. This is done by using some of the engine thrust by tapping into the mechanical shaft power and converting it into electrical power.

The electrical machine can also be used to electrically start the aircraft engine, like on the Trent 1000 for the Boeing 787 Dreamliner.

Power electronic system

The power electronic system includes power switches tasked to convert dc waveforms into ac waveforms and vice versa.

Working with the power electronic system is the control system; together they manage the flow of voltages and currents to accurately control the electrical machine with the desired speed and torque.

The control system

The brains of the electrical system.

It hosts complex algorithms that determine what the voltage and current waveforms should be to create a certain amount of speed and torque for the electrical machine. This is like making a precise decision every micro second.

Getting this right enables the whole electrical system to work safely and reliably.

Electrical machine

Attached to the gas turbine engine shaft, it can electrically start the engine. It can also act as a generator to convert mechanical shaft power from the gas turbine engine into electrical power.