As the leader of the Green & High-Tech programme, what is your main focus?

Our Green & High-Tech programme concentrates on electrification, alternative fuels, exhaust gas after-treatment, digitisation, and overall system capability – in other words, offering complete drive, propulsion and power generation systems.

The diesel engine drives that we offer today are already highly evolved and have excellent efficiency. However using cutting-edge exhaust gas after-treatment systems will enable us to lower pollutant emissions even further. By integrating the engine and exhaust gas after-treatment system, you can assure the overall efficiency and perfect interaction of both components. This will be enhanced by the other technologies we are working on – keeping both the life-cycle costs of our marine propulsion systems down, and improving their ecological footprint.

For marine propulsion and rail traction, hybrid drive solutions using electric motors will be one of the pillars of green mobility in the future. The world's largest sailing yacht, 'Sailing Yacht A', was recently commissioned, and is powered by an innovative hybrid propulsion system from MTU that is tailored to the needs of the customer. This is a combined diesel-electric propulsion system offering seven different drive modes. Diesel engines and electric motors are configured together to achieve high speeds and low-vibration cruising with reduced fuel consumption.

Our subsidiary, Bergen Engines, recently embarked on a project to power the new expedition vessels being launched by Hurtigruten, the renowned Norwegian cruise operator. These hybrid propulsion systems stand to make the dream of emission-free maritime traffic in highly sensitive natural environments such as the Arctic waters, become reality as early as 2019.

Mobile gas engines

Our Green & High-Tech programme also involves work on mobile gas engines. These are gas engines powered by conventional natural gas or regeneratively produced green natural gas. Natural gas can be stored on vessels in the form of Compressed Natural Gas (CNG) and Liquid Natural Gas (LNG). These engines boast excellent environmental credentials and will be instrumental in reducing the impact of maritime traffic on the environment, permanently lowering emissions. Compared to a diesel engine, a straightforward gas engine generates up to 11% less greenhouse gas, 90% fewer nitrogen oxides, virtually no particulates, and no sulphur dioxides.

If we also deploy wind and solar energy for producing synthetic natural gases, we will reach an important milestone in the development of maritime industry energy. Power-to-Gas technology enables ocean-going vessels to be powered by regeneratively produced fuels.

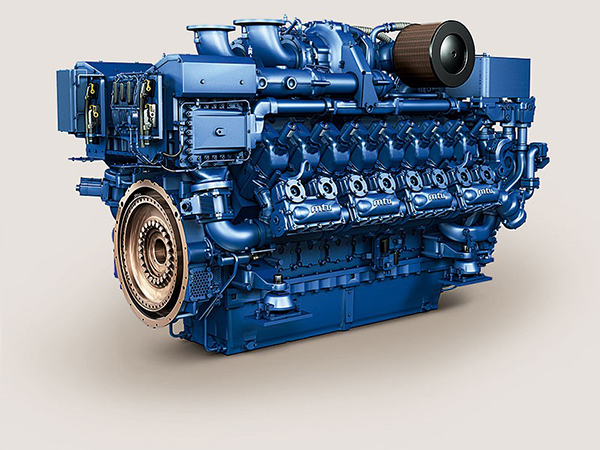

The new MTU 16V 4000 gas engine for commercial marine applications

Our gas engines are already developed – with Damen Shipyards set to install the first test engines in tugboats for the Svitzer towage company. From 2018 onwards we will be delivering our first series-production gas engines, certified for use in commercial shipping. In the North Sea, Dutch shipping company Doeksen will be deploying our gas engines to power its ferries circulating in the Wadden Sea offshore nature reserve. As well as this there is a new ferry scheduled to go into service in 2019 that will operate on Lake Constance, Europe's biggest drinking water reservoir. This ferry will run solely on LNG. We are delighted to see our propulsion systems being selected for service in sensitive eco-systems like these. This is irrefutable proof that our business is on the right course.

What is the next challenge for Green & High-Tech?

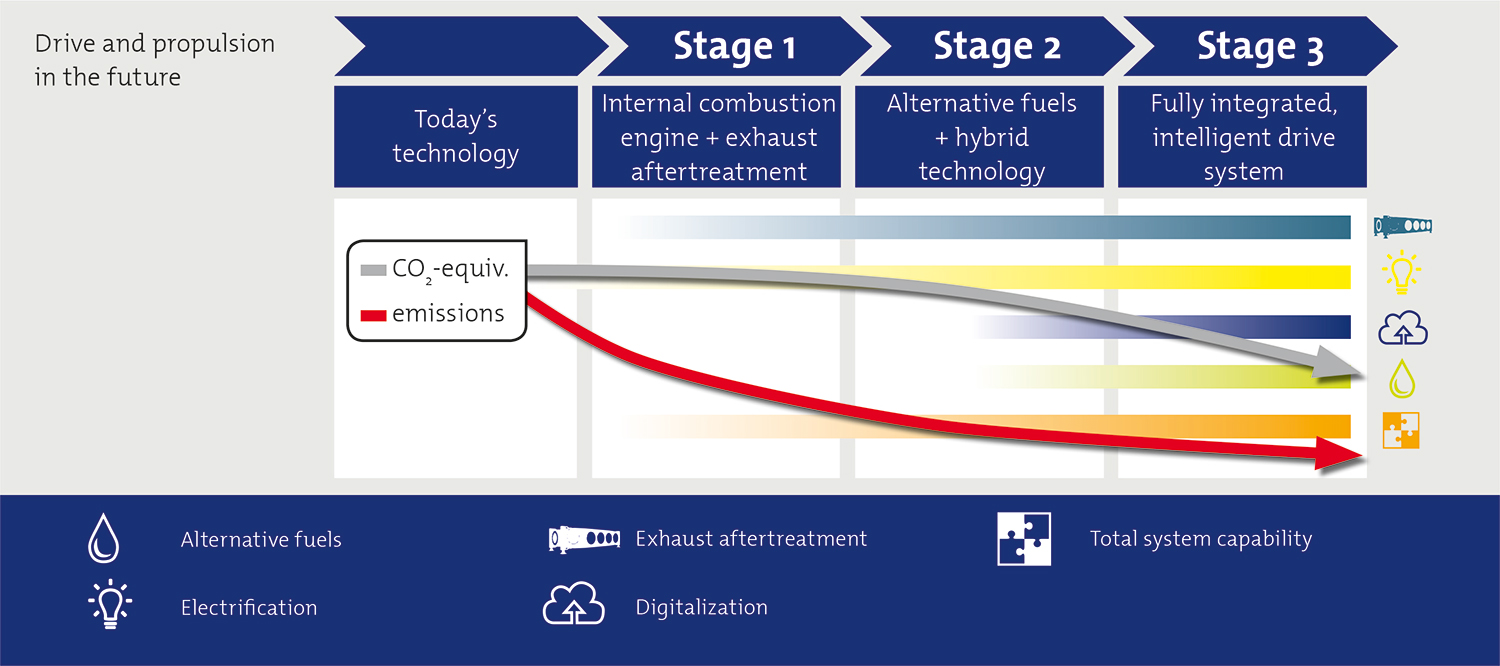

We are amalgamating different technologies to produce an optimum system with significantly lower pollutant emissions, and a better carbon footprint than conventional drives, based on internal combustion engines.

In the first phase, the internal combustion engine is combined with an exhaust gas after-treatment system. Gas then comes into play as an alternative fuel. In the second phase, we add other components such as the electric motors we deploy in our E-drive solutions. We then use intelligent, networked products to optimize maintenance processes and enhance material efficiency. In the third phase, we use sustainably produced fuels to significantly lower emissions and fuel consumption.

This chart shows a propulsion system that combines an internal combustion engine with technologies from our Green & High-Tech Programme. The outcome is a fully integrated and highly evolved overall system that incorporates efficient technologies to protect our environment.